Jewellery Casting Service

DISCOVER THE MAGIC

Jewellery Casting Services

Are you aiming to create unique jewelry pieces with intricate designs? Jewelry casting services could be the perfect solution for you. This specialized process allows designers to transform their imaginative and complex ideas into exquisite jewelry pieces. Whether you’re interested in gold jewelry casting services or silver jewelry casting services, these methods cater to a wide array of preferences and designs. With gold casting, the allure and value of your piece are enhanced, offering a timeless appeal. On the other hand, silver casting provides a versatile and classic look that suits various styles. By choosing the right type of jewelry casting service, you can bring your unique vision to life with precision and beauty.

Jewellery Casting Services

Jewellery Casting Services

The casting process kicks off with a thorough consultation to explore your design ideas, requirements, and material preferences. During this initial discussion, our expert team will guide you through choosing the right materials, ensuring they align with your vision and the piece’s functionality. To help refine your design, we offer suggestions and creative input, drawing from years of experience in jewelry crafting. Once we have a solid understanding of your desired outcome, we employ computer-aided design (CAD) software to create a precise digital model of your custom piece. This model serves as a blueprint for the wax model and, eventually, the final jewelry item, allowing us to tweak and perfect every detail before moving forward.

Jewellery Casting Services

After finalizing the design, we proceed with wax model creation. This step utilizes state-of-the-art 3D printing technology to produce an exact wax replica of your custom design. Creating this model is crucial as it guarantees precision in the casting process. By perfectly mirroring your intended design, the wax model ensures that the final jewelry piece aligns closely with your expectations in both detail and quality. This careful preparation is essential in achieving an accurate and satisfactory outcome in the finished product, maintaining the high standards of craftsmanship and detail that Bamina Jewelry is known for.

Jewellery Casting Services

Mold preparation investment is a pivotal stage in the jewellery casting process. In this step, the wax model of your design is encased in a special investment material. This mixture, primarily made of plaster and other binding agents, is crucial for capturing every intricate detail of the wax model. The application of the investment material is done with precision to ensure all fine lines and textures are preserved. Once it hardens, the investment forms a solid mold. This mold is essential as it serves as the vessel for casting the molten metal in the subsequent steps, bringing your custom jewelry design closer to reality.

Jewellery Casting Services

In the wax removal burnout stage, the real magic happens. The mold containing the wax model is placed inside a kiln. Here, it undergoes a crucial burnout process. During this phase, the wax inside the mold melts away completely. This leaves behind a perfect cavity in the exact shape of your custom jewelry design. The high temperatures also serve another vital purpose. They remove any residual moisture and help to harden the investment material that forms the mold. This preparation is essential as it readies the mold for the metal casting process. Thus, ensuring that your design will be flawlessly realized in metal.

Jewellery Casting Services

With the mold now prepared, the exciting part of metal casting begins. We carefully pour molten metal into the cavity of the mold, forming the solid framework of your custom jewelry piece. The type of metal used varies based on your preferences and the specific requirements of your design. You can choose from several options, including gold and silver, each adding a distinct character and value to the finished piece. This process not only captures all the intricate details of your design but also ensures the strength and durability of your jewelry. Once the metal cools and solidifies, it’s ready for the next stages of refinement and detailing, where it will be polished and perfected to meet the highest standards of quality and craftsmanship.

Jewellery Casting Services

Jewellery Casting Services

Once the main structure of your jewelry is cast, it’s time for the detailed finishing work. Artisans file, polish, and sometimes solder the metal to refine the shape and surface to your specifications. This stage is where the piece truly begins to sparkle as every facet is smoothed and shined.

If your design features gemstones, this is also when they come into play. Our skilled artisans meticulously set each stone using the best technique for the design and stone type. Options include prong setting, which allows the most light exposure for the stones; bezel setting, which encircles them with a rim of metal for protection; and pave setting, known for its paved, glittering surface. This careful work ensures that the stones are not only secure but also beautifully integrated into the final piece, highlighting your design’s brilliance and craftsmanship.

Transformative Casting Journey

Jewellery Casting Services

Jewellery casting services have the extraordinary ability to transform your initial sketches and concepts into stunning, tangible pieces of jewelry. This transformation is not just about making a piece of metal into something wearable; it’s about realizing your artistic vision in its fullest form. Each step in the casting process plays a pivotal role, meticulously crafting and refining the materials to meet your exact specifications. From the precision of the initial design development to the final polish in the finishing stage, every detail is considered to ensure your piece is not only beautiful but also a true representation of your original idea. Are you excited to see your unique designs come to life? Jewellery casting is a gateway to turning those dreams into exquisite reality, providing you with a way to create something truly unique and personal. Whether you’re an aspiring designer or a seasoned artist, this service offers you a golden opportunity to expand your creative horizons. Ready to embark on a creative journey with jewellery casting? Start exploring today and see where your creativity can take you!

Create Your Design

Related Posts

Why Work with a Turkish Silver Jewellery Supplier?

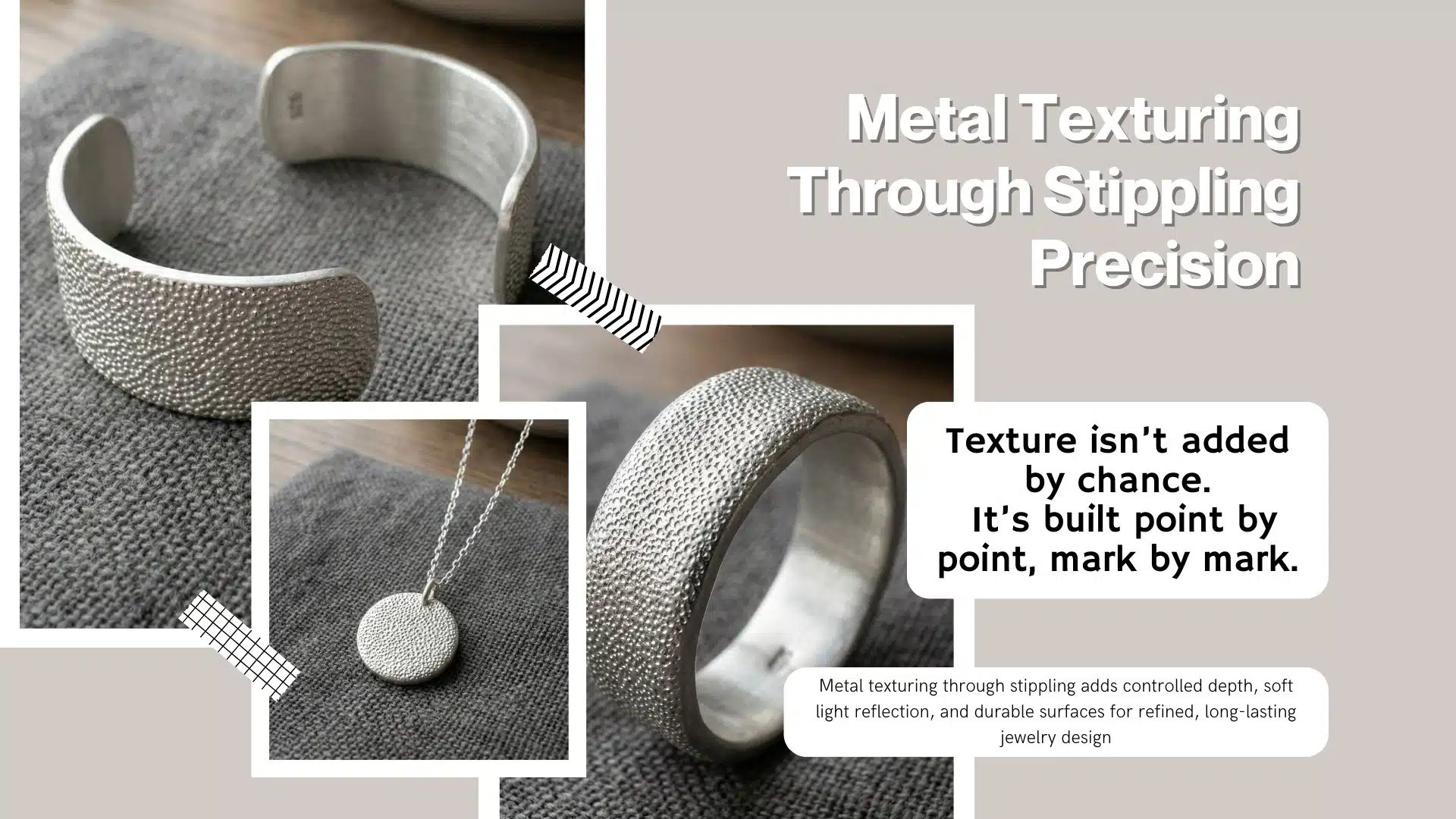

Jewelry design does not rely on form alone. Surface treatment plays a powerful role in how a piece feels, reflects light, and communicates character. Metal Texturing through stippling introduces depth and personality without changing the overall shape. This technique transforms smooth metal into a tactile surface that feels intentional and expressive

Metal Texturing Through Stippling Precision

Jewelry design does not rely on form alone. Surface treatment plays a powerful role in how a piece feels, reflects light, and communicates character. Metal Texturing through stippling introduces depth and personality without changing the overall shape. This technique transforms smooth metal into a tactile surface that feels intentional and expressive

2026 Color, Texture, and Finish Trends in Jewelry Design

Jewelry design evolves with culture, emotion, and lifestyle. In 2026, designers move toward balance, depth, and tactile expression. 2026 Jewelry Trends show a clear shift away from sharp contrasts and heavy decoration toward refined color, thoughtful texture, and intentional finishes. These elements work together to create jewelry that feels calm, modern, and wearable.

What Jewelry Brands Must Prepare Before Working with a Manufacturer

Working with a jewelry manufacturer can accelerate brand growth, but preparation determines results. Many delays and misunderstandings come from missing information rather than poor execution. Understanding how to prepare for jewelry production helps brands move confidently from idea to finished product. Strong preparation saves time, controls cost, and builds trust with manufacturing partners.

Gold, Silver, and Gemstones: Which Jewelry Holds Its Value Best?

Many people buy jewelry for style or emotion. However, some also think about long-term value. This raises an important question: which jewelry truly holds its worth over time? For those starting out, Jewelry as Investment for Beginners offers a useful framework. Understanding materials, market behavior, and craftsmanship helps buyers make smarter choices without chasing trends.