Transforming Metal into Stunning Artistic Creations

jewelry wax casting

In the ever-evolving landscape of jewelry design, the need for high-quality casting services is more crucial than ever. Bamina Jewelry stands as a leading provider of top-notch jewellery casting services. We cater to a diverse clientele, including designers, brands, and individuals, all seeking to create custom pieces. With our skilled team of artisans and cutting-edge technology, we ensure that your designs are brought to life with unparalleled precision and attention to detail. So, let’s delve into the various aspects of our casting wax for jewelry.

jewelry wax casting

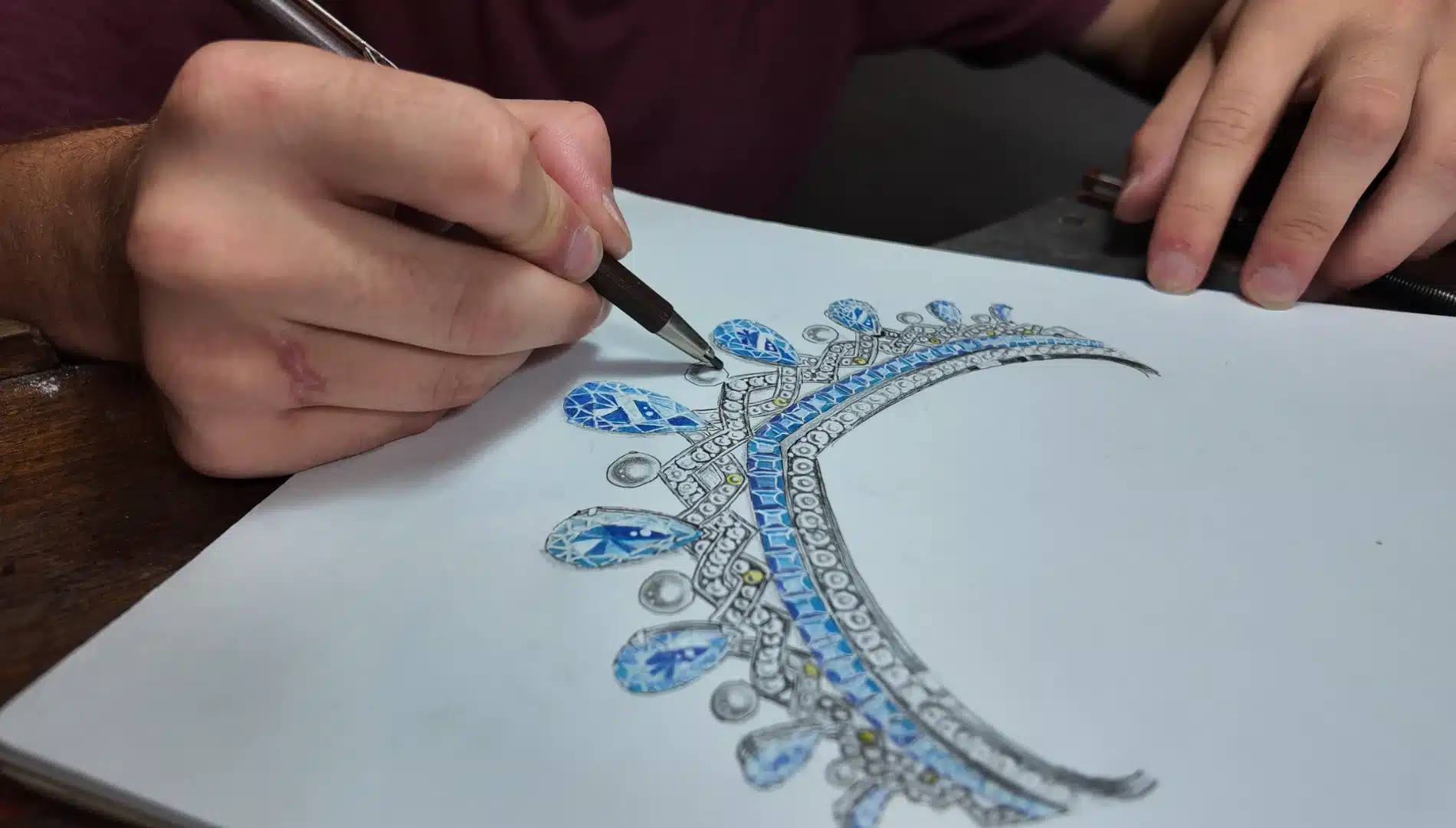

Initially, the process kicks off with the crafting of a silver master. Serving as the foundational blueprint, this original model is pivotal for the subsequent creation of rubber molds. Furthermore, craftsmen meticulously design the silver master, ensuring it captures every nuance and detail that will appear in the final piece. Therefore, the silver master acts as a critical first step, setting the stage for the quality and intricacy of the end product.

jewelry wax casting

After meticulously preparing the silver master, the subsequent step in our process is to craft rubber molds. These molds serve a crucial role, acting as the foundational templates for the wax models that come next. At Bamina Jewelry, we place an unwavering focus on precision during this phase. Why? Because doing so is pivotal for ensuring the highest quality in the final product that emerges later on.

jewelry wax casting

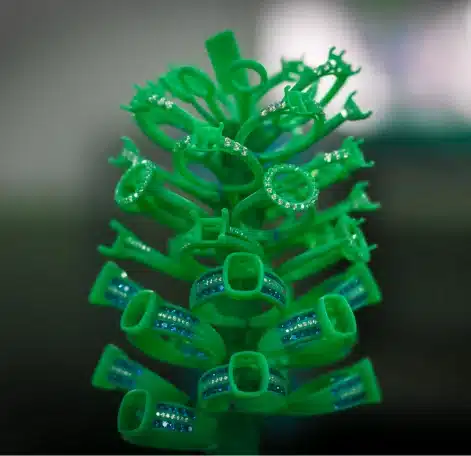

Subsequently, the focus shifts to the machinery, which plays an indispensable role in the casting process. Specifically, a commercial wax injector machine takes center stage at this juncture. Once the rubber mold is meticulously prepared and ready, it then gets seamlessly installed into this machine. Consequently, the machine injects the wax, thereby setting the stage for the next critical steps in the casting process.

jewelry wax casting

Furthermore, the machine pumps molten wax into the mold cavity under pressure. This crucial step forms the wax models used later for casting. The pressure ensures the wax fills every part of the mold, capturing all intricate details from the silver master.

jewellery MANUFACTURING

You might wonder why we at Bamina Jewelry, and many in the industry prefer it. This method offers unmatched precision and allows for complex designs that traditional methods might not achieve. Additionally, it’s a cost-effective way to produce high-quality pieces, benefiting both manufacturers and consumers.

jewelry wax casting

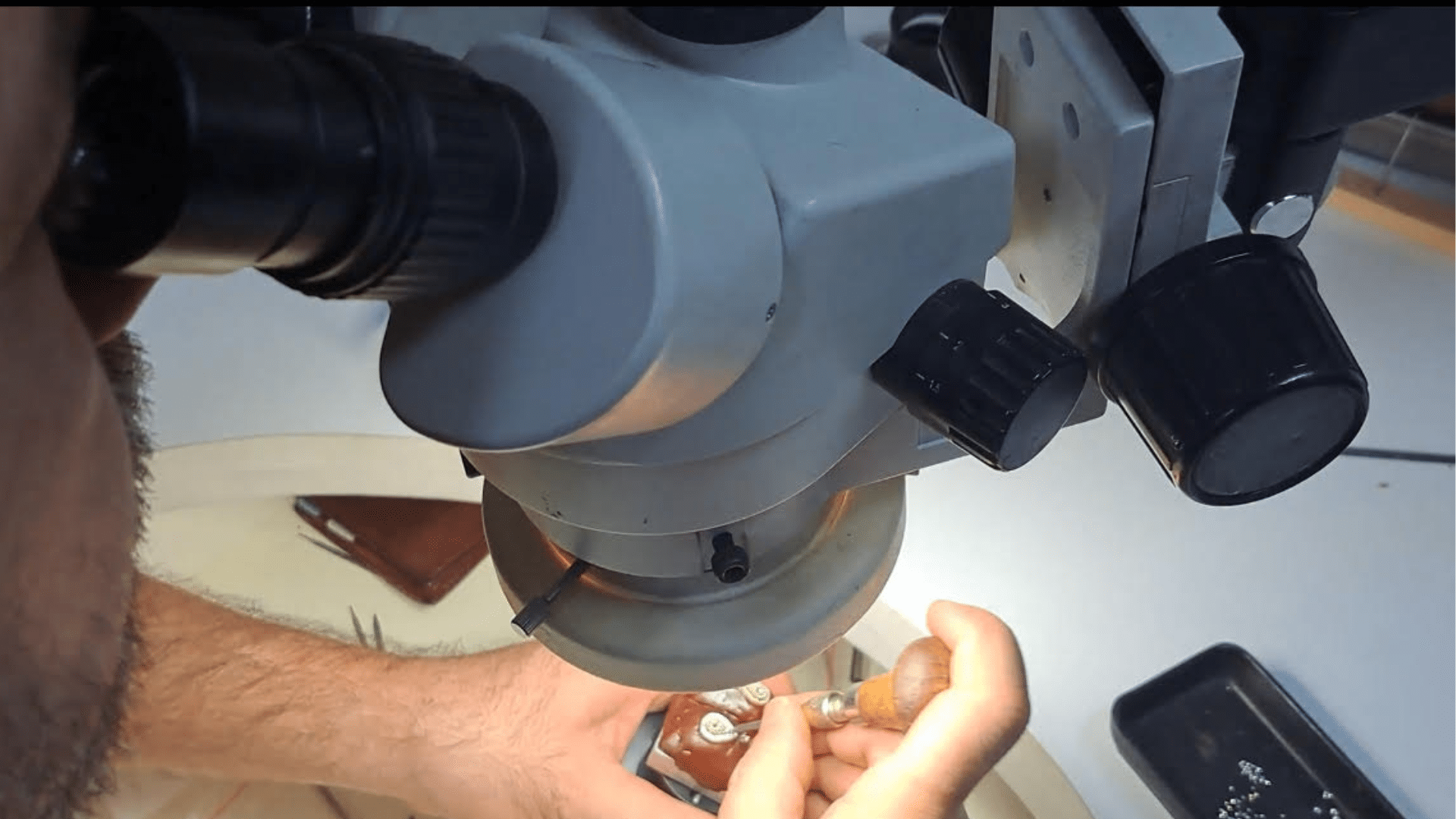

Moreover, quality control stands as a pivotal aspect of the entire process. We meticulously examine each wax model to guarantee it aligns with the stringent quality benchmarks established by the original silver master. Should we discover any flaws or imperfections, we promptly address and correct them at this particular stage. Afterward, and only then, do we proceed to the next step in the process.

jewellery MANUFACTURING

Lastly, the wax models serve as the foundation for the final, crucial step in the jewelry-making process. Through a technique commonly referred to as lost-wax casting, the wax gets replaced by the desired metal. Consequently, this transformation results in a breathtaking piece that flawlessly mirrors the original silver master in every intricate detail.

A Fusion of Precision, Artistry, and Innovation

jewelry wax casting

In summary, this intricate process seamlessly blends technology and craftsmanship in a truly remarkable manner. Starting with the initial silver master and culminating in the final, exquisite product, each step is executed with unparalleled precision and meticulous care. Particularly in specialized jewelry businesses, this attention to detail is paramount. As the demand for unique, high-quality jewelry continues to surge, the role of wax casting in fulfilling this growing need becomes increasingly vital and indispensable.