OEM Jewelry Manufacturer

OEM Jewelry Manufacturing Process

As an OEM (Original Equipment Manufacturer) jewelry manufacturer, our primary goal is to provide businesses with high-quality, custom jewelry that embodies their brand’s identity and caters to their specific needs. We will outline our approach to OEM jewelry manufacturing, detailing each step to provide insight into how we work to create exceptional jewelry pieces for your business.

OEM Jewelry Manufacturing Process

Our collaboration begins with a comprehensive consultation where we learn about your business, target audience, and specific requirements. This enables us to tailor our services to meet your needs, ensuring that the jewelry we produce aligns with your brand identity and appeals to your customers.

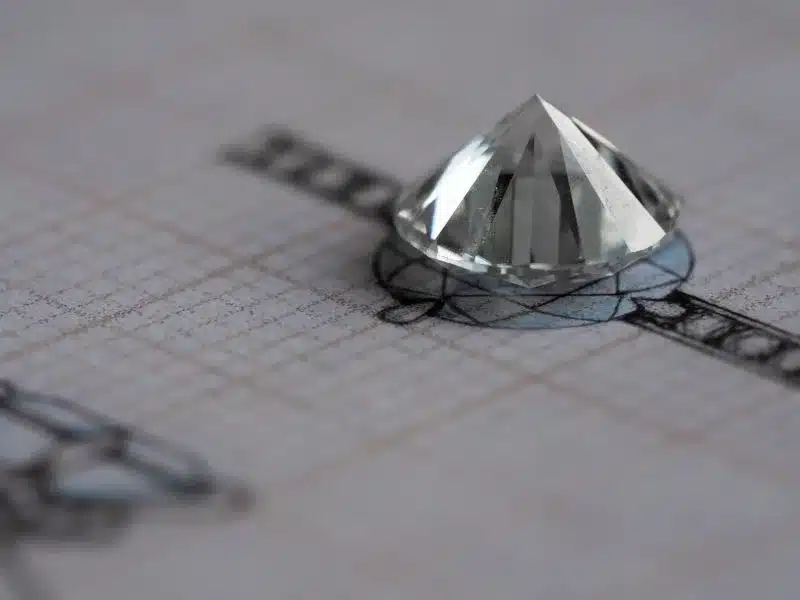

Based on your design ideas, brand guidelines, or existing product line, our skilled designers work closely with your team to create a series of sketches or 3D digital models that represent the proposed designs. This collaborative stage allows for open communication and adjustments, ensuring that the final designs align with your brand aesthetic and meet your approval.

Once the designs are approved, we guide you through choosing the right materials and gemstones for your custom pieces. Our expert team helps you select the ideal metal type, color, and gemstones based on factors such as aesthetics, durability, and budget, keeping your target audience in mind.

As the designs and materials are finalized, our talented craftsmen employ various techniques, such as lost wax casting, hand fabrication, or metal 3D printing, to create the metal components of your jewelry pieces. The choice of technique depends on factors like design intricacy, production volume, and desired level of detail.

Our skilled jewelers then set the gemstones using techniques like prong, bezel, or channel settings, ensuring they are securely held in place while enhancing their beauty. Once the stones are set, the jewelry pieces undergo finishing and polishing, refining the metal surface and applying the desired finish for a stunning final product.

Timely Delivery and Ongoing Support

Upon passing the inspection, your OEM jewelry pieces are carefully packaged and delivered to your business. We pride ourselves on offering timely delivery and ongoing support to ensure your satisfaction and foster a long-lasting partnership.

Our OEM jewelry manufacturing process focuses on understanding your business needs, collaborating with your team, and employing skilled craftsmanship to create exceptional jewelry pieces that resonate with your brand and customers. From the initial consultation to the final delivery, our dedicated team works diligently to ensure that our OEM jewelry services exceed your expectations and contribute to your business’s success.