The Craft of Custom Jewelry Making

Creating custom jewelry

is a mesmerizing blend of art, craftsmanship, and personal expression. From the first conceptualization to the final polished piece, each custom jewelry item serves as a unique testament to both the wearer’s vision and the jeweler’s skill. This blog delves into the detailed process involved in bringing custom jewelry to life, offering insight into the artistry and technical expertise that transform ideas into tangible, cherished treasures. From Concept to Creation: The Craft of Custom Jewelry Making highlights the journey that turns inspiration into a timeless work of art.

From Concept to Creation: The Craft of Custom Jewelry Making

Capturing the Client’s Vision

The process begins with an in-depth consultation where the client and the jeweler discuss the vision, purpose, and inspiration behind the piece. This stage is crucial for setting the groundwork for the design, involving key decisions about materials, gemstones, and budget. It’s a collaborative effort to ensure that the final product echoes the client’s desires and stays within their financial means.

From Concept to Creation: The Craft of Custom Jewelry Making

Creating the Blueprint

After clarifying the client’s requirements, the jeweler sketches preliminary designs. This creative phase may involve traditional drawing or utilizing Computer-Aided Design (CAD) software to produce detailed and accurate representations. These initial sketches act as the blueprint for the jewelry piece and are refined until they perfectly align with the client’s vision.

From Concept to Creation: The Craft of Custom Jewelry Making

Transitioning from Design to Tangible Form

Once the design is approved, a wax model is crafted. This pivotal step transforms the design from a two-dimensional sketch to a three-dimensional prototype. The wax model provides a physical preview of the final jewelry piece, allowing the client to make any necessary modifications to the design or fit before the piece is cast in metal.

From Concept to Creation: The Craft of Custom Jewelry Making

From Wax to Precious Metal

The creation of the jewelry piece truly begins with the casting process. The wax model is used to create a mold, into which molten metal—selected from options like gold, silver, platinum, or another material—is poured. After the metal cools and solidifies, the mold is broken away to reveal the rough casting of the jewelry, which is then meticulously cleaned and prepped for further enhancements.

From Concept to Creation: The Craft of Custom Jewelry Making

Embellishing with Precision

If the design includes gemstones, the next step involves the precise and careful setting of stones. They must be securely embedded and aligned with the overall aesthetics. The piece then undergoes a thorough polishing process to enhance its luster and smooth any imperfections. Additional textural details or finishes may also be applied to achieve the final desired look.

The Signature of Individuality

The Craft of Custom Jewelry Making

The creation of custom jewelry is not just about crafting a piece of adornment; it’s a deeply personal journey that reflects the client’s individual story, style, and sentiments. Each step, from the initial consultation to the final presentation, is infused with meticulous attention to detail and commitment, ensuring that the final piece is not only exquisite but also a meaningful emblem that will be treasured for generations. Whether commemorating a special occasion or expressing a personal style, custom jewelry stands out as a symbol of individuality and artistic passion.

Create Your Design

Related Posts

2026 Color, Texture, and Finish Trends in Jewelry Design

Jewelry design evolves with culture, emotion, and lifestyle. In 2026, designers move toward balance, depth, and tactile expression. 2026 Jewelry Trends show a clear shift away from sharp contrasts and heavy decoration toward refined color, thoughtful texture, and intentional finishes. These elements work together to create jewelry that feels calm, modern, and wearable.

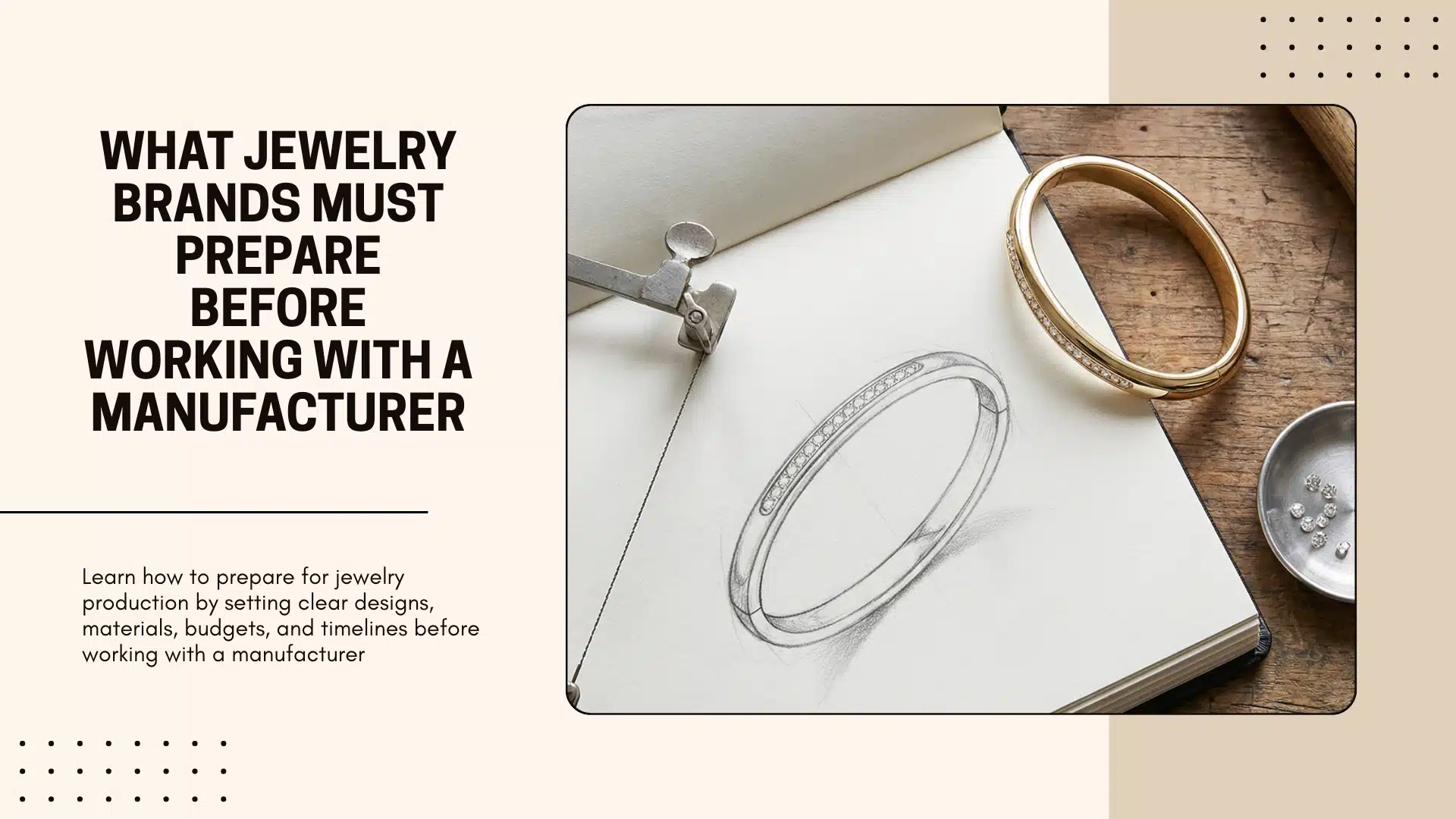

What Jewelry Brands Must Prepare Before Working with a Manufacturer

Working with a jewelry manufacturer can accelerate brand growth, but preparation determines results. Many delays and misunderstandings come from missing information rather than poor execution. Understanding how to prepare for jewelry production helps brands move confidently from idea to finished product. Strong preparation saves time, controls cost, and builds trust with manufacturing partners.

Gold, Silver, and Gemstones: Which Jewelry Holds Its Value Best?

Many people buy jewelry for style or emotion. However, some also think about long-term value. This raises an important question: which jewelry truly holds its worth over time? For those starting out, Jewelry as Investment for Beginners offers a useful framework. Understanding materials, market behavior, and craftsmanship helps buyers make smarter choices without chasing trends.

Benefits of AI-Generated Jewelry Design for Brands and Startups

Jewelry design has always balanced creativity and precision. Today, technology adds a new layer to this balance. Artificial intelligence now supports designers in exploring ideas faster and smarter. The Benefits of AI-Generated Jewelry Design for Brands appear most clearly for startups and growing labels that need speed, flexibility, and cost control without losing creativity.

Birthstones, Engravings, and Symbols: Meaningful Details for Custom Jewellery Gifts

Jewellery becomes powerful when it tells a story. A simple ring or pendant can hold deep emotion when it includes personal elements. This is why Meaningful Details for Custom Jewellery Gifts matter so much. Birthstones, engravings, and symbols turn beautiful objects into personal keepsakes. These small choices often define the emotional value of the piece.