Introduction to Rubber Mold Casting

rubber mold jewelry casting

Rubber mold jewelry casting offers a fantastic gateway into the intricate world of jewelry making. This technique is celebrated for its precision and versatility, enabling both novice and seasoned crafters to produce exquisite pieces. Let’s delve into how this method works and why it’s so beneficial for jewelry artisans.

rubber mold jewelry casting

The first step in rubber mold jewellery casting involves creating a detailed model, usually crafted from wax. This model is the exact replica of the final jewelry piece you wish to create. It is meticulous work, but absolutely crucial as it sets the foundation for your entire casting process.

rubber mold jewelry casting

After the model is ready, it is encased in a liquid rubber compound. This rubber is then allowed to harden around the wax model. The curing process forms a sturdy yet flexible mold that captures every intricate detail of the original design. The precision here is key, as it determines the quality of all subsequent reproductions.

rubber mold jewelry casting

Once the rubber mold is set, the wax model inside is melted and drained away. This leaves a hollow cavity in the shape of the original jewelry piece. It’s this cavity that will be filled in the next step of the process. Here, the real magic happens as the design begins to take tangible form.

rubber mold jewellery casting

Metal is melted to a liquid state and then poured into the hollow cavity of the rubber mold. Metals typically used include silver, gold, or platinum, depending on the jeweler’s preference and the piece’s design requirements. The metal cools inside the mold, solidifying into the shape of the original wax model.

rubber mold jewelry casting

After the metal has cooled and solidified, the rubber mold is carefully peeled away. What emerges is a rough version of the finished jewelry piece. It may require some cleaning and polishing to bring out its full beauty, but the most intricate parts of the design are perfectly replicated thanks to the rubber mold.

rubber mold jewelry casting

This technique’s beauty lies in its ability to produce multiple copies of the same piece, all with the same intricate details and exquisite craftsmanship as the original. Rubber mold jewellery casting not only saves time but also ensures consistency across multiple productions, which is invaluable for both bespoke creations and larger production runs.

The Artistic and Practical Merits

rubber mold jewelry casting

In summary, rubber mold jewellery casting is a skillful blend of art and science, ideal for crafting detailed and consistent jewelry pieces. It allows jewelers to experiment with different materials and designs, pushing the boundaries of creativity. With practice, anyone can master this technique, opening up endless possibilities in the world of jewelry design.

Create Your Design

Related Posts

2026 Color, Texture, and Finish Trends in Jewelry Design

Jewelry design evolves with culture, emotion, and lifestyle. In 2026, designers move toward balance, depth, and tactile expression. 2026 Jewelry Trends show a clear shift away from sharp contrasts and heavy decoration toward refined color, thoughtful texture, and intentional finishes. These elements work together to create jewelry that feels calm, modern, and wearable.

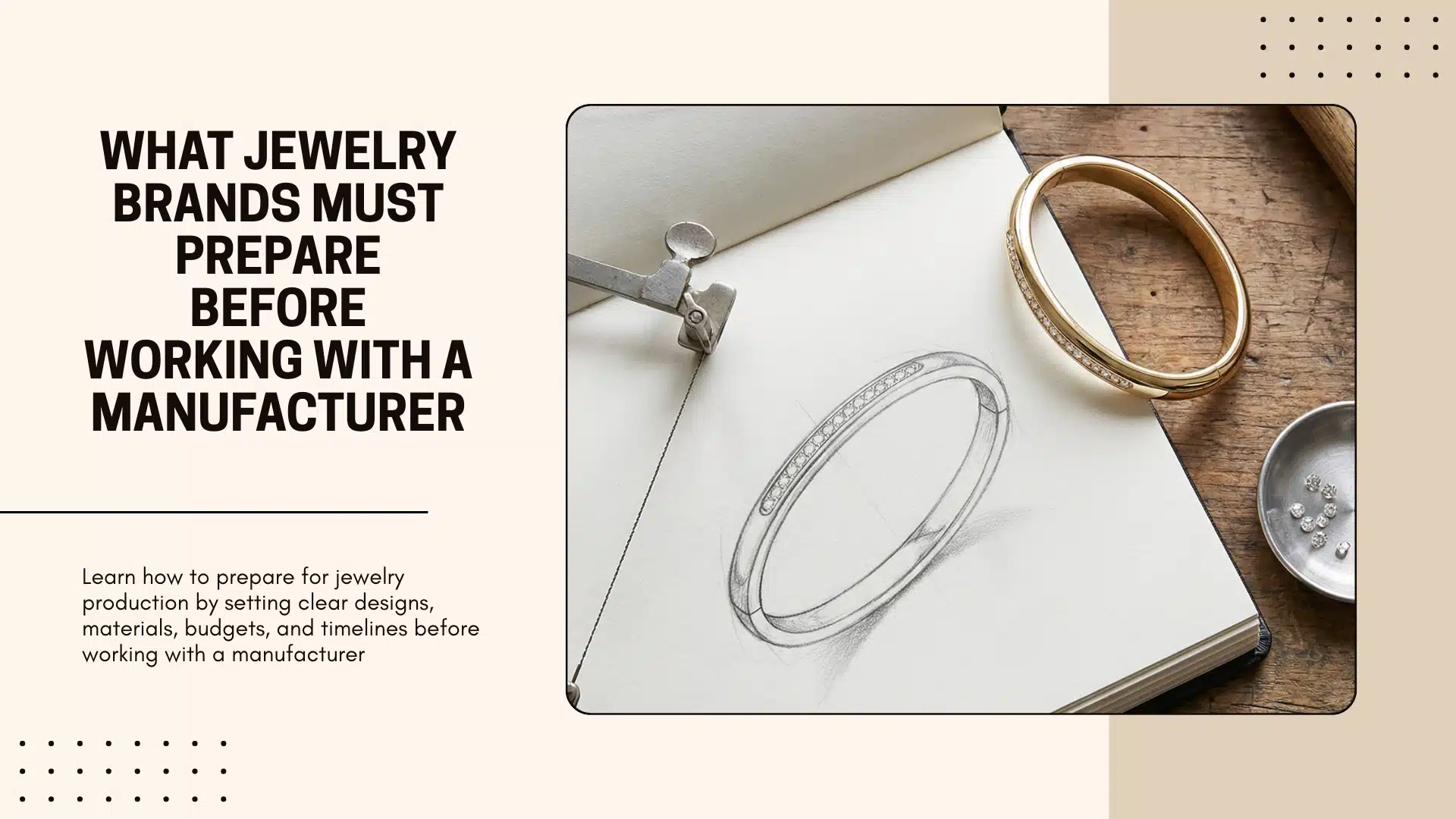

What Jewelry Brands Must Prepare Before Working with a Manufacturer

Working with a jewelry manufacturer can accelerate brand growth, but preparation determines results. Many delays and misunderstandings come from missing information rather than poor execution. Understanding how to prepare for jewelry production helps brands move confidently from idea to finished product. Strong preparation saves time, controls cost, and builds trust with manufacturing partners.

Gold, Silver, and Gemstones: Which Jewelry Holds Its Value Best?

Many people buy jewelry for style or emotion. However, some also think about long-term value. This raises an important question: which jewelry truly holds its worth over time? For those starting out, Jewelry as Investment for Beginners offers a useful framework. Understanding materials, market behavior, and craftsmanship helps buyers make smarter choices without chasing trends.

Benefits of AI-Generated Jewelry Design for Brands and Startups

Jewelry design has always balanced creativity and precision. Today, technology adds a new layer to this balance. Artificial intelligence now supports designers in exploring ideas faster and smarter. The Benefits of AI-Generated Jewelry Design for Brands appear most clearly for startups and growing labels that need speed, flexibility, and cost control without losing creativity.

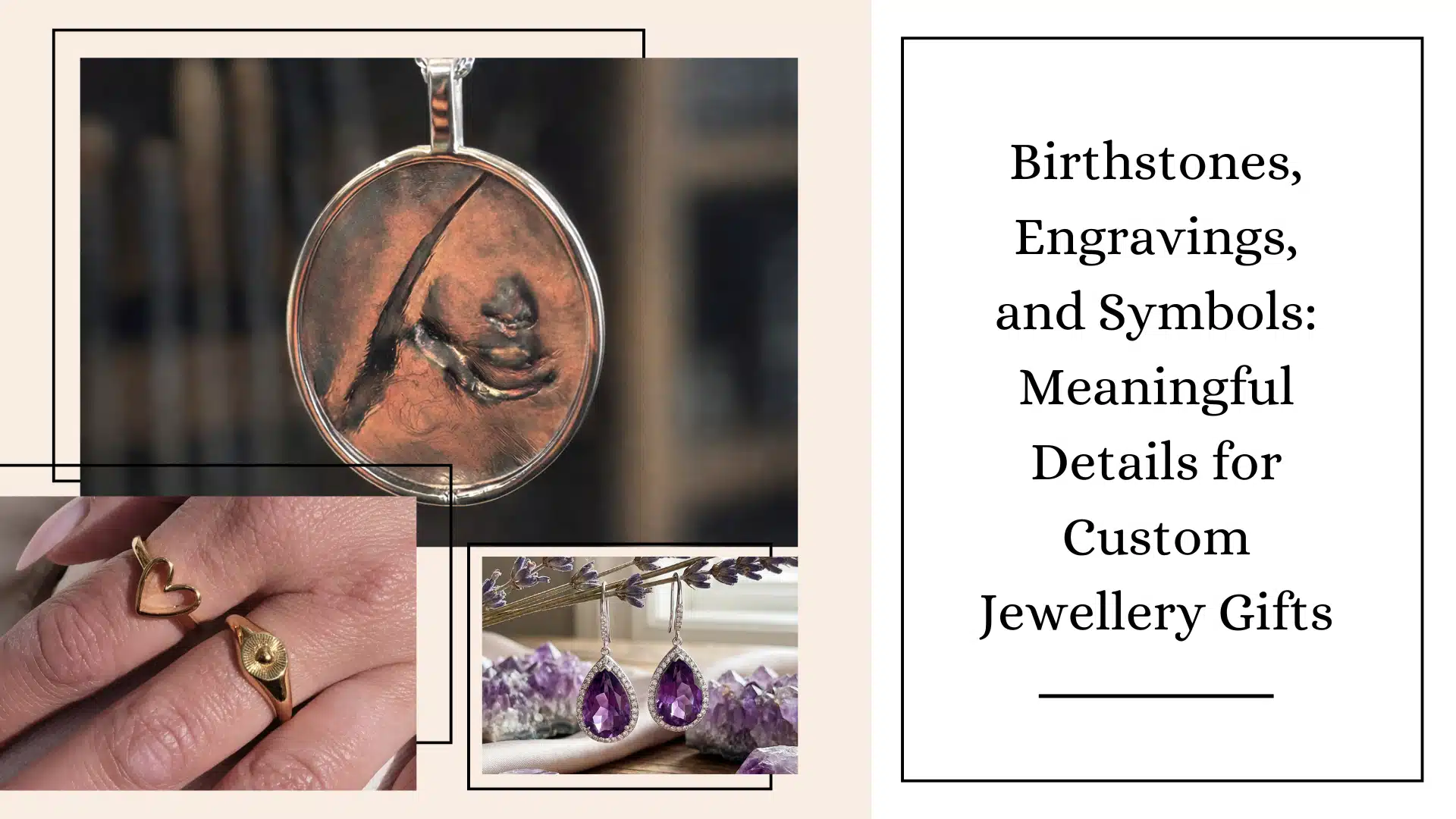

Birthstones, Engravings, and Symbols: Meaningful Details for Custom Jewellery Gifts

Jewellery becomes powerful when it tells a story. A simple ring or pendant can hold deep emotion when it includes personal elements. This is why Meaningful Details for Custom Jewellery Gifts matter so much. Birthstones, engravings, and symbols turn beautiful objects into personal keepsakes. These small choices often define the emotional value of the piece.