The Art of Lost Wax Casting

Lost wax casting, also known as investment casting, is a method used to create precise and intricate jewelry designs. The technique involves creating a wax model of the item, which is then encased in a mold. The wax is melted away, leaving a cavity that is filled with molten metal to form the jewelry piece. This method is ideal for producing high-quality and detailed pieces in metals like gold, silver, and platinum.

Understanding Lost Wax Casting in Jewelry Manufacturing

The first step in lost wax casting is designing the jewelry piece. Jewelers or designers sketch their ideas, which are then sculpted or molded in wax. The wax model can be carved by hand or printed using a 3D printer, allowing for precise details and complex designs that would be difficult or impossible to achieve through traditional metalworking techniques.

Understanding Lost Wax Casting in Jewelry Manufacturing

Once the wax model is ready, it’s encased in a heat-resistant investment material to create a mold. This investment is typically made of plaster or a similar substance, which needs to be strong enough to withstand the high temperatures of molten metal. The wax model and investment are placed in a flask, leaving the wax encased in the investment material.

Understanding Lost Wax Casting in Jewelry Manufacturing

The next step involves the removal of the wax. This is done by placing the flask in a kiln, where it is heated to a high temperature. The heat causes the wax to melt and flow out, leaving behind a hollow mold. This is why the process is referred to as “lost wax” casting—the original wax model is lost in the process.

Understanding Lost Wax Casting in Jewelry Manufacturing

With the wax removed, molten metal is poured into the cavity left by the wax. This can be done using gravity or with the assistance of centrifugal or vacuum casting machines to ensure that the metal fills every detail of the mold. Once the metal cools and solidifies, the investment material is broken away, revealing the newly formed jewelry piece.

Understanding Lost Wax Casting in Jewelry Manufacturing

The casting is then cleaned and polished. Any additional processes such as setting stones, engraving, or further polishing are carried out to finish the piece. The result is a beautiful, detailed piece of jewelry that is exactly as the designer envisioned.

The Impact of Lost Wax Casting on Jewelry Manufacturing

Understanding Lost Wax Casting in Jewelry Manufacturing

Lost wax casting is a fascinating and ancient technique used in jewelry manufacturing that allows for intricate details and complex designs. This process has been refined over the centuries and remains a cornerstone of the jewelry industry today. In this blog, we’ll explore the steps involved in lost wax casting and how it impacts the quality and creativity of jewelry pieces.

Create Your Design

Related Posts

2026 Color, Texture, and Finish Trends in Jewelry Design

Jewelry design evolves with culture, emotion, and lifestyle. In 2026, designers move toward balance, depth, and tactile expression. 2026 Jewelry Trends show a clear shift away from sharp contrasts and heavy decoration toward refined color, thoughtful texture, and intentional finishes. These elements work together to create jewelry that feels calm, modern, and wearable.

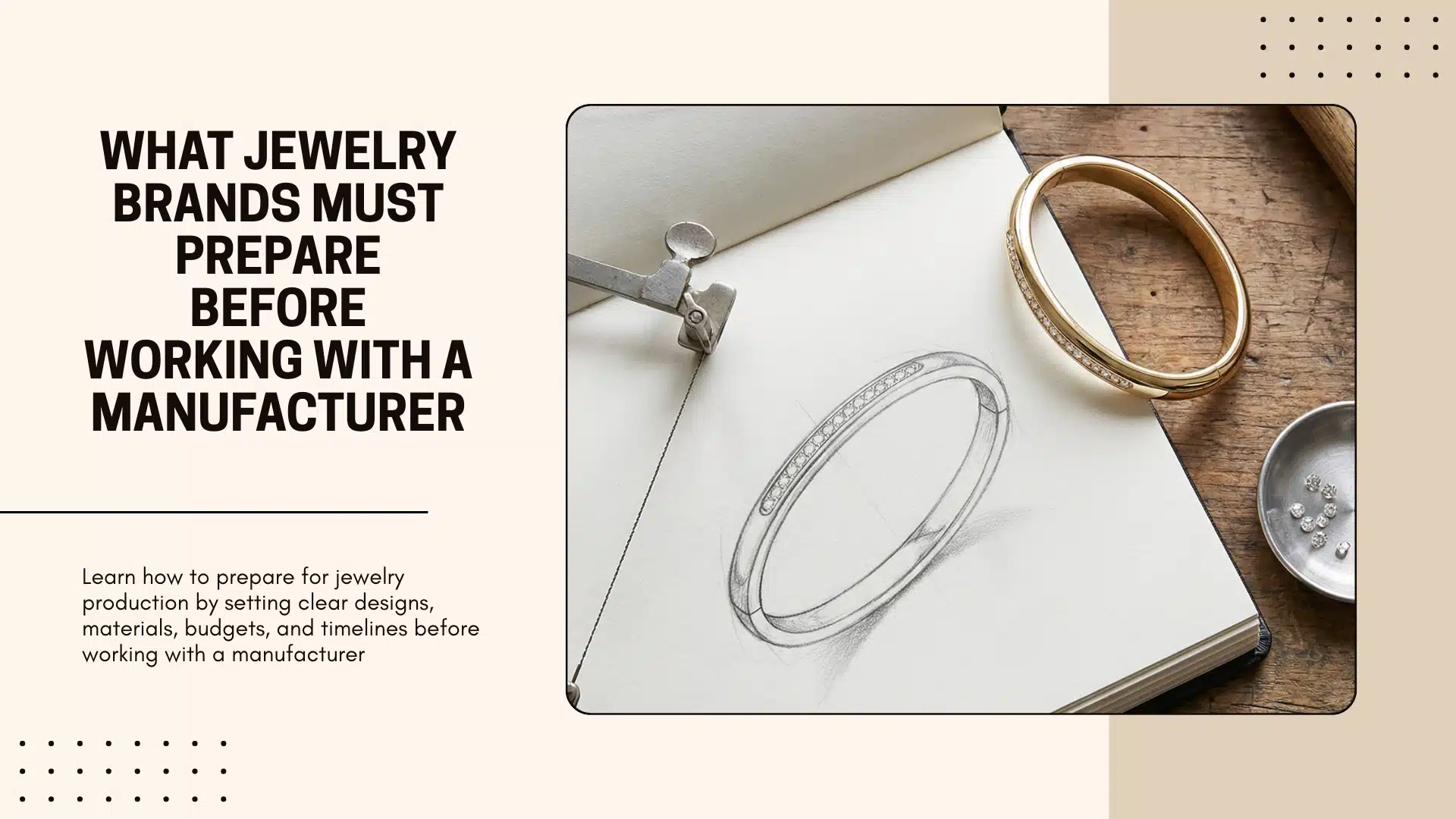

What Jewelry Brands Must Prepare Before Working with a Manufacturer

Working with a jewelry manufacturer can accelerate brand growth, but preparation determines results. Many delays and misunderstandings come from missing information rather than poor execution. Understanding how to prepare for jewelry production helps brands move confidently from idea to finished product. Strong preparation saves time, controls cost, and builds trust with manufacturing partners.

Gold, Silver, and Gemstones: Which Jewelry Holds Its Value Best?

Many people buy jewelry for style or emotion. However, some also think about long-term value. This raises an important question: which jewelry truly holds its worth over time? For those starting out, Jewelry as Investment for Beginners offers a useful framework. Understanding materials, market behavior, and craftsmanship helps buyers make smarter choices without chasing trends.

Benefits of AI-Generated Jewelry Design for Brands and Startups

Jewelry design has always balanced creativity and precision. Today, technology adds a new layer to this balance. Artificial intelligence now supports designers in exploring ideas faster and smarter. The Benefits of AI-Generated Jewelry Design for Brands appear most clearly for startups and growing labels that need speed, flexibility, and cost control without losing creativity.

Birthstones, Engravings, and Symbols: Meaningful Details for Custom Jewellery Gifts

Jewellery becomes powerful when it tells a story. A simple ring or pendant can hold deep emotion when it includes personal elements. This is why Meaningful Details for Custom Jewellery Gifts matter so much. Birthstones, engravings, and symbols turn beautiful objects into personal keepsakes. These small choices often define the emotional value of the piece.