Soldering holds jewelry together—literally. It joins metal parts, secures structures, and ensures durability. Without proper soldering, even the best design fails over time. This is why understanding the Types of Jewelry Soldering is essential for designers, manufacturers, and brands. Each solder type behaves differently under heat and affects strength, appearance, and repairability.

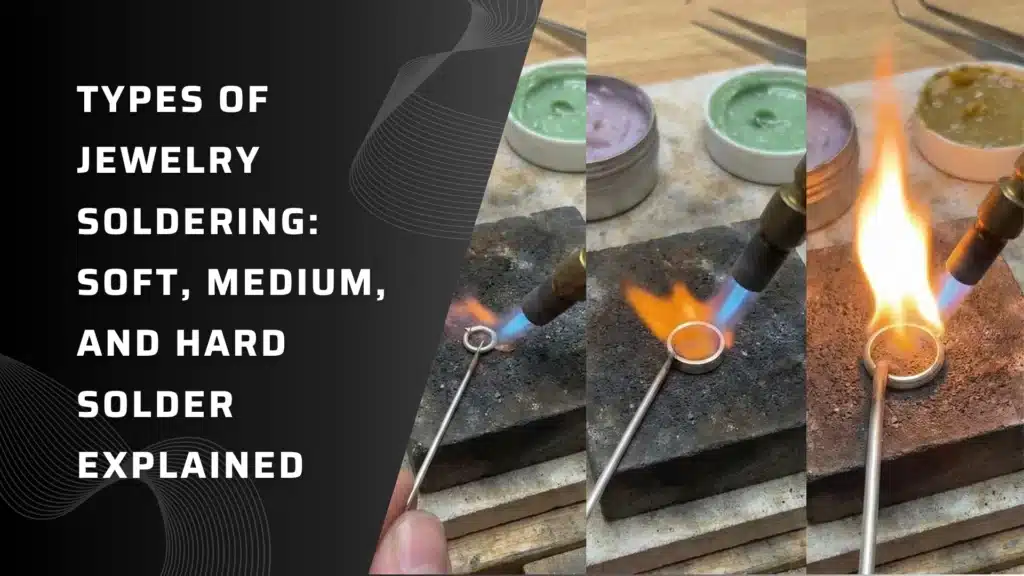

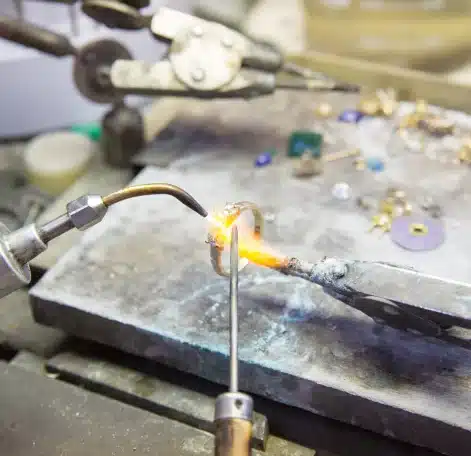

Jewelry soldering uses a filler metal with a lower melting point than the main metal. Heat melts the solder, not the jewelry itself, allowing parts to bond. In the Types of Jewelry Soldering, the main difference lies in melting temperature and strength. Choosing the right solder helps control heat flow and prevents damage to finished surfaces or stones.

Hard solder melts at the highest temperature among the Types of Jewelry Soldering. Jewelers often use it early in the construction process. It creates strong joints that resist stress and wear. Because of its high melting point, hard solder works best before adding delicate details or stones. Designers rely on it for structural areas such as ring shanks and chain links.

Medium solder melts at a slightly lower temperature than hard solder. It offers a balance between strength and control. In the Types of Jewelry Soldering, medium solder works well during mid-stage assembly. Jewelers use it to add components without re-melting earlier joints. This flexibility makes it ideal for complex designs that require multiple soldering steps.

Soft solder melts at the lowest temperature. It allows jewelers to work close to finished areas or stones. Among the Types of Jewelry Soldering, soft solder suits final adjustments and repairs. While it provides less strength than hard or medium solder, it offers precision and reduced heat risk. Jewelers often choose it for delicate elements or post-polish fixes.

Successful jewelry construction often uses more than one solder type. Jewelers start with hard solder, move to medium, and finish with soft solder. This sequence reflects best practice within the Types of Jewelry Soldering. Each step lowers heat exposure while preserving earlier joints. Choosing correctly protects design integrity and reduces rework.