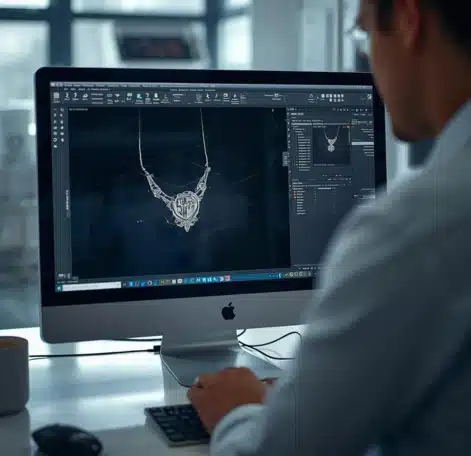

Jewelry has always been a blend of artistry and precision. Today, technology adds a new layer to that craft. The Role of Computer-Aided Jewelry Design in Modern Manufacturing is transforming how designers create, test, and produce each piece. Using advanced software, artisans can visualize designs in detail before the first mold is made. This digital revolution bridges traditional craftsmanship with modern efficiency, reshaping how fine jewelry is imagined and brought to life.

To understand The Role of Computer-Aided Jewelry Design in Modern Manufacturing, it helps to look back. Jewelry once relied solely on hand sketches and wax carvings. Every adjustment required time and new materials. With the arrival of 3D modeling and CAD software, the process changed forever. Designers can now create accurate models, experiment with shapes, and perfect proportions virtually. This evolution enhances precision and creativity, allowing complex designs to become reality faster and more efficiently.

One of the most significant aspects of The Role of Computer-Aided Jewelry Design in Modern Manufacturing is how it balances creativity with accuracy. CAD tools give artisans complete control over symmetry, structure, and scale. Small details like prong thickness, stone alignment, or band curvature can be adjusted with micron-level precision. This not only ensures visual harmony but also guarantees structural integrity. Designers can experiment freely, knowing that every element can be refined digitally before production begins.

The connection between technology and craftsmanship defines The Role of Computer-Aided Jewelry Design in Modern Manufacturing. Once a design is complete, it moves into rapid prototyping through 3D printing or wax milling. These methods allow designers to test proportions, balance, and comfort. Every digital design becomes a tangible prototype ready for casting and finishing. The seamless transition from software to workshop reduces human error and accelerates the entire production cycle, ensuring perfection in every curve and contour.

Sustainability plays a growing role in modern jewelry production. The Role of Computer-Aided Jewelry Design in Modern Manufacturing supports this shift by minimizing waste. CAD software calculates exact material requirements, reducing excess metal and stone use. Mistakes that once required recasting or re-polishing can now be identified digitally. This efficiency not only saves time but also supports environmentally responsible practices—a growing priority for brands and consumers alike.

Another benefit of The Role of Computer-Aided Jewelry Design in Modern Manufacturing is how it enhances collaboration. Designers, clients, and craftsmen can view digital renderings in real time, making instant changes to color, texture, or setting. This flexibility improves communication and reduces misunderstandings. It also expands the possibilities for custom jewelry, allowing clients to visualize their unique designs before production. The result is a personalized experience where innovation meets emotion.