OEM Jewelry Manufacturing Process

Understanding

OEM Jewelry Manufacturing

As an OEM (Original Equipment Manufacturer) jewelry manufacturer, our primary goal is to provide businesses with high-quality, custom jewelry that embodies their brand’s identity and caters to their specific needs. We will outline our approach to OEM jewelry manufacturing, detailing each step to provide insight into how we work to create exceptional jewelry pieces for your business.

OEM Jewelry Manufacturer

Collaborating on Design

First, these manufacturers work closely with brands to meet specific design needs. They start by making prototypes and samples. This step ensures every detail is right before full-scale production begins.

Sourcing Materials

Next, they find and buy the required materials, like gold and silver. They always ensure these materials meet high standards. This practice guarantees the final product is of top quality.

Handling Production

Then, the actual production takes place. These manufacturers use modern technology and skilled craftsmanship. They manage everything from casting and molding to the final touches and quality checks.

Managing Logistics

Finally, managing logistics is crucial. Efficient delivery systems ensure products reach markets on time. This is vital for maintaining customer satisfaction and trust.

OEM Jewelry Manufacturer

Cost Optimization

By working with OEMs, brands can reduce costs significantly. This is because production happens in areas where labor and materials are cheaper. This advantage allows brands to price their products competitively.

Quality and Innovation

OEM manufacturers are always improving. They invest in new technologies and processes. This commitment enhances both the quality and innovation of the products.

Market Growth

These partnerships make it easier for new brands to enter the market. They don’t have to invest heavily in production facilities. This lowers the barriers to entry and spurs industry growth.

OEM jewellery manufacturer

Embracing Sustainability

There is a growing shift towards sustainability. Manufacturers are starting to use eco-friendly materials and processes.

Adopting New Technologies

Technologies like 3D printing and AI are becoming more common. They are changing how jewelry is designed and produced.

Increasing Customization

Customers want products tailored to their preferences. Therefore, manufacturers are investing in flexible production methods. This trend allows for more personalization.

OEM Jewelry Manufacturer

Our OEM jewelry manufacturing process focuses on understanding your business needs, collaborating with your team, and employing skilled craftsmanship to create exceptional jewelry pieces that resonate with your brand and customers. From the initial consultation to the final delivery, our dedicated team works diligently to ensure that our OEM jewelry services exceed your expectations and contribute to your business’s success.

Create Your Design

Related Posts

2026 Color, Texture, and Finish Trends in Jewelry Design

Jewelry design evolves with culture, emotion, and lifestyle. In 2026, designers move toward balance, depth, and tactile expression. 2026 Jewelry Trends show a clear shift away from sharp contrasts and heavy decoration toward refined color, thoughtful texture, and intentional finishes. These elements work together to create jewelry that feels calm, modern, and wearable.

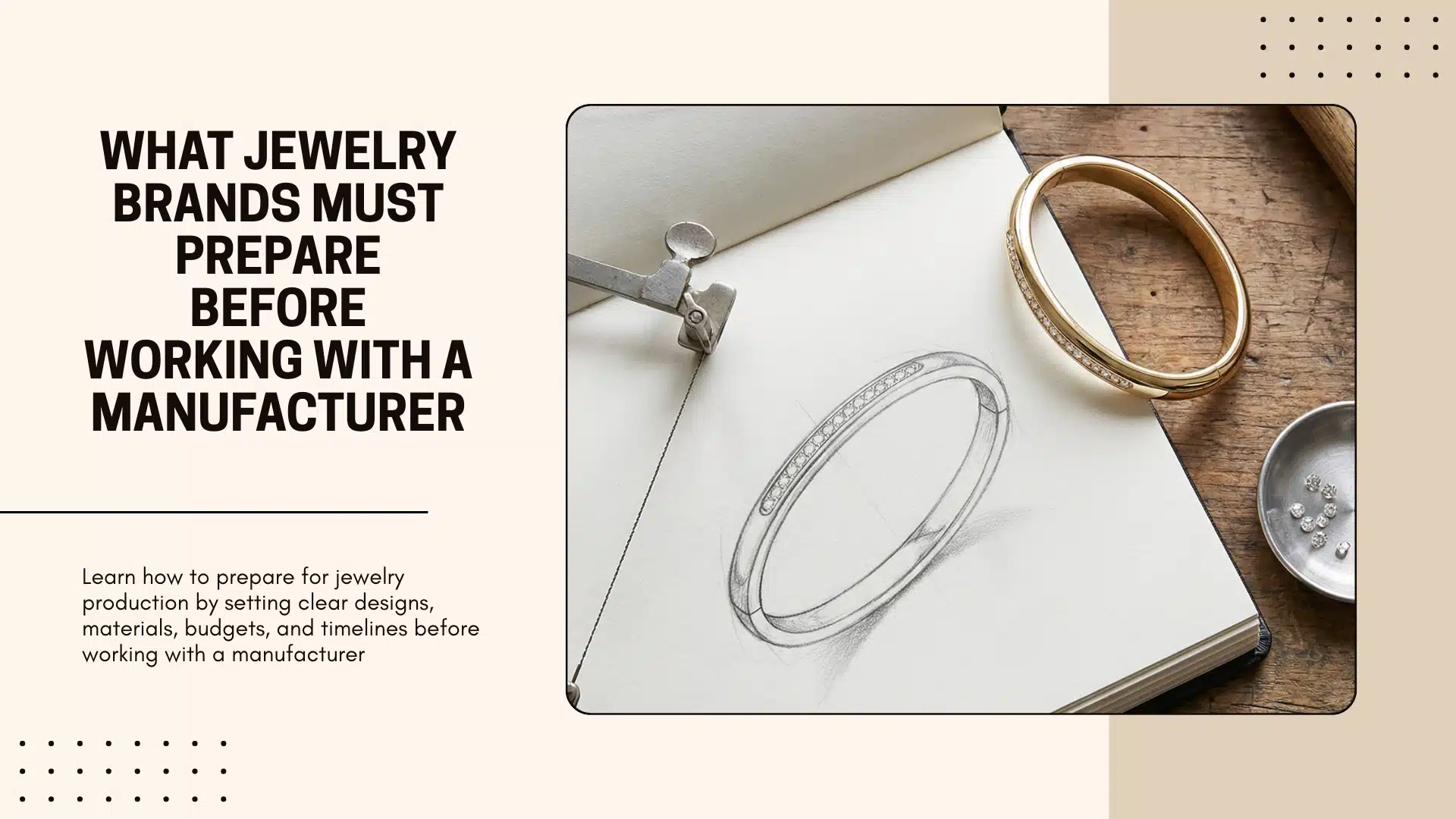

What Jewelry Brands Must Prepare Before Working with a Manufacturer

Working with a jewelry manufacturer can accelerate brand growth, but preparation determines results. Many delays and misunderstandings come from missing information rather than poor execution. Understanding how to prepare for jewelry production helps brands move confidently from idea to finished product. Strong preparation saves time, controls cost, and builds trust with manufacturing partners.

Gold, Silver, and Gemstones: Which Jewelry Holds Its Value Best?

Many people buy jewelry for style or emotion. However, some also think about long-term value. This raises an important question: which jewelry truly holds its worth over time? For those starting out, Jewelry as Investment for Beginners offers a useful framework. Understanding materials, market behavior, and craftsmanship helps buyers make smarter choices without chasing trends.

Benefits of AI-Generated Jewelry Design for Brands and Startups

Jewelry design has always balanced creativity and precision. Today, technology adds a new layer to this balance. Artificial intelligence now supports designers in exploring ideas faster and smarter. The Benefits of AI-Generated Jewelry Design for Brands appear most clearly for startups and growing labels that need speed, flexibility, and cost control without losing creativity.

Birthstones, Engravings, and Symbols: Meaningful Details for Custom Jewellery Gifts

Jewellery becomes powerful when it tells a story. A simple ring or pendant can hold deep emotion when it includes personal elements. This is why Meaningful Details for Custom Jewellery Gifts matter so much. Birthstones, engravings, and symbols turn beautiful objects into personal keepsakes. These small choices often define the emotional value of the piece.