Custom jewelry starts with an idea, but it succeeds through execution. At every stage, balance matters—creativity must meet accuracy. This is exactly Where Design Meets Precision. Our manufacturing process transforms concepts into wearable pieces through careful planning, technical control, and skilled craftsmanship. Each step builds on the last, ensuring the final piece reflects both vision and quality.

Every project begins with understanding. We listen closely to design ideas, references, and expectations. Sketches, inspiration images, or written concepts all help shape direction. This early phase is Where Design Meets Precision for the first time. Clear communication prevents mistakes later. By aligning proportions, style, and function early, we create a strong foundation for production.

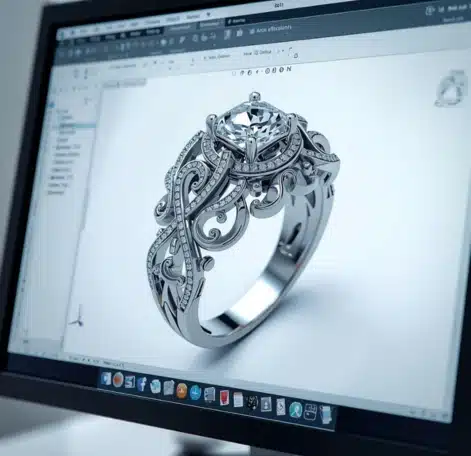

Once the concept is defined, we move into 3D modeling. CAD allows us to refine every curve, surface, and measurement. At this stage, Where Design Meets Precision becomes visible. We adjust wall thickness, prong strength, and stone settings to ensure durability and comfort. Digital modeling also allows clients to review details before physical production begins, reducing risk and saving time.

Designs must prove themselves in physical form. We create prototypes to test scale, weight, and wearability. This stage is critical because it reveals how a piece behaves beyond the screen. Here again, Where Design Meets Precision guides decisions. We identify weak points, refine balance, and confirm finishes. Sampling builds confidence before moving into full production.

After approval, production begins. Casting turns digital models into metal form. Skilled setters place stones with care, ensuring security and alignment. Polishing then brings surfaces to life. Throughout these steps, Where Design Meets Precision remains the focus. Each process follows strict quality standards to maintain consistency and strength without losing design intent.

Quality does not rely on one final check. We monitor weight, structure, and finish throughout production. This continuous control shows Where Design Meets Precision in action. Weight consistency protects pricing and durability. Visual inspection ensures symmetry and clean details. Functional checks confirm comfort and wearability. These steps protect both the product and the brand behind it.