Precision defines quality in modern jewellery design. Every curve, wall, and prong must balance beauty and durability. Following jewellery DFM guidelines—Design for Manufacturability principles—helps designers create pieces that are both elegant and practical to produce. Wall thickness and prong strength play central roles in this process. When these details are well-designed, the final product achieves longevity, comfort, and flawless finishing.

Wall thickness is one of the first considerations in jewellery DFM guidelines. If walls are too thin, castings may distort, crack, or fail during polishing. Too thick, and the piece becomes heavy and wasteful in material. Ideal wall thickness ensures strength while maintaining aesthetic balance. For most fine jewellery, walls between 0.6 mm and 1.2 mm achieve the right mix of durability and lightness. Proper wall design also supports even metal flow during casting, preventing porosity and shrinkage.

Prongs are more than decorative—they are structural supports for gemstones. Jewellery DFM guidelines emphasize the need for balanced prong strength. A prong that’s too thin risks bending or breaking, while one that’s too thick hides the stone’s brilliance. The ideal prong width depends on stone size and type. For smaller stones, 0.7–0.9 mm prongs work best, while larger stones need 1.0–1.3 mm for secure setting. Strong, well-positioned prongs ensure stones stay stable during wear, polishing, and setting.

Designers often walk a fine line between beauty and practicality. According to jewellery DFM guidelines, maintaining wall thickness and prong strength must never compromise design intent. The key lies in proportion. For example, a thin band can appear delicate yet still hold strength if its inner surface remains reinforced. Similarly, prongs can appear elegant if slightly tapered but strong at the base. By applying structural awareness early in the design stage, designers achieve both visual harmony and mechanical stability.

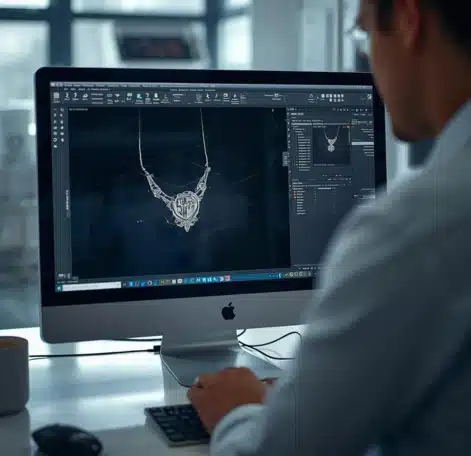

Even experienced designers make errors when wall thickness or prongs are neglected. Jewellery DFM guidelines recommend avoiding excessively thin walls around pavé settings, as they weaken the structure. Overly thick metal behind stones adds unnecessary weight and reduces comfort. Another common issue is uneven prong height, which affects stone alignment and polishing access. By reviewing these factors during 3D modeling and before printing, designers can prevent costly reworks and casting failures.

Modern CAD tools have revolutionized how designers apply jewellery DFM guidelines. Digital simulations reveal weak areas, measure wall consistency, and test prong tension before production. Designers can adjust thickness instantly and visualize real-world stress points. These insights improve accuracy and efficiency while reducing material waste. Advanced rendering and 3D printing further validate designs, ensuring every prong, wall, and curve performs as intended once cast in metal.